At K&S Machining, we offer premium production machining services throughout the Gulf Coast region including Alabama where we frequently serve the defense and aerospace industries among others. With our precision equipment, consulting solutions, and ITAR registration, our production machining in Alabama offers local businesses the benefits of precision fabrication from accuracy to efficiency.

Pinpoint Accuracy in Machined Parts

Machined parts with low tolerances are integral to the defense and aerospace industries, which is why our Alabama clients get the benefit of our precision machined parts. With state-of-the-art CNC mills, routers, and mill-turn lathes, we can achieve precision accuracy alongside brief turnaround times all while maintaining quality. In addition to the tight tolerances we achieve, we also maintain a quality assurance program that is ISO compliant. This program combined with our pending AS9100 certification ensures that any machining errors are caught and corrected long before any of our Alabama customers receive their custom machined parts.

We Serve Tier 1 and Tier 2 Defense Industry Suppliers in Alabama

At K&S Machining, we have experience serving both Tier 1 and Tier 2 defense industry suppliers throughout the state and the wider Gulf Coast region. Both Tier 1 and Tier 2 suppliers require precision accuracy in their machined parts, and we have the experience necessary to provide Tier 1 suppliers with the pieces required to complete engines, landing gear, braking systems, and other components for the defense industry.

Our Tier 2 efforts are generally less complex, but we still prioritize accuracy and reliability in all our machined parts. These suppliers are adept at making parts such as missile nose cones, flight controls, and airframe structures, and we have the machining capability to streamline that process. At K&S, we strive to function as an extension of our customers’ manufacturing operations integrating our work seamlessly into their processes.

Personalized Service in Alabama

While quality and reliability is an integral aspect to any kind of machining work, we offer our customers in Alabama enhanced customizability as well. We have design experts that will work with you to come up with the best solution for your needs while still maintaining the close tolerances that parts need. When you reach out to our team, you will be put in touch with a real human who can offer a personalized service to get you the parts that you need with prompt turnaround times and competitive pricing.

A lot of shops throughout Alabama focus solely on production, but our personalized service lets you enjoy design consulting as well. If we see room for improvements in the design that could streamline the process even further, we will work with your team to make any necessary changes you approve of before we start prototyping. Designing with machinability in mind is key for any kind of parts that are going to enter the production process at a larger scale.

Initial Review of Plans

At the beginning of any machining job, we conduct a thorough review of all drawings and plans for the machined parts. This allows us to not only get a full understanding of the machined part that needs to be created but also what the part is going to be used for. By understanding it on both levels, we are able to optimize processes and enhance efficiency to create a more reliable and precise machining process all while having the potential to decrease costs. For example, a prototype part for something that is going to eventually have a high production volume is going to be approached differently from a part that customers won’t need very many copies of.

Our Advanced Equipment for Production Machining in Alabama

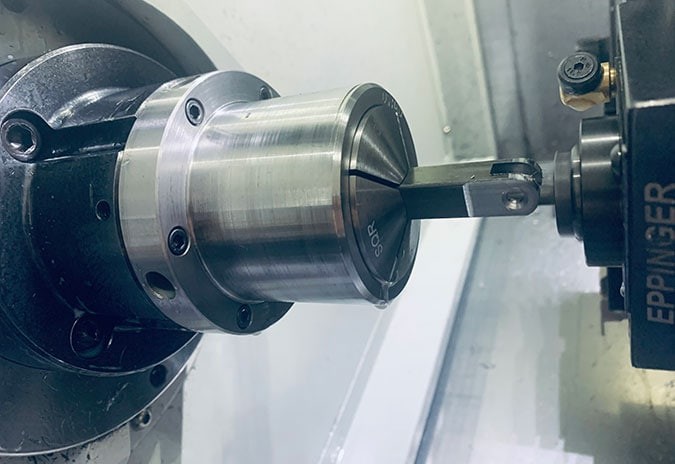

To achieve tight tolerances and precision, we utilize state-of-the-art equipment at our Alabama shop. This equipment includes mill-turn lathes, programmable routers, and CNC milling centers among others. Our machining centers are made from reliable brands such as Tsugami, Lync, and Hyundai Wia, so they are compatible with a range of materials. The following are just a few of the materials that our machines excel at working with.

- Steels (low carbon, alloy, and stainless)

- Brass

- Aluminum

- Plastic

- Rhodium

Production Machining in Alabama From a ITAR Registered Machine Shop

K&S Machining has achieved ITAR registration, which allows us to work with the defense industry with our prototype design and manufacturing work. This allows us to offer our personalized service to defense contractors throughout Alabama and the Gulf Coast area. In fact, our convenient location in Alabama makes shipping prototype parts to Mississippi, Tennessee, and Louisiana easy. Additionally, we can serve aerospace and oil and gas manufacturers with the precision parts needed all while maintaining tight tolerances.

Contact Us for Production Machining in Alabama

K&S Machining is a full-service machine shop in Alabama that works as a partner to your manufacturing needs with the capability of machining parts and optimizing designs and plans before prototyping even begins. As your trusted source for production machining in Alabama, we will optimize your prototype for machinability and functionality before machining the actual part. Request a quote today for your prototype, and our team will get to work reviewing your prototype plans.