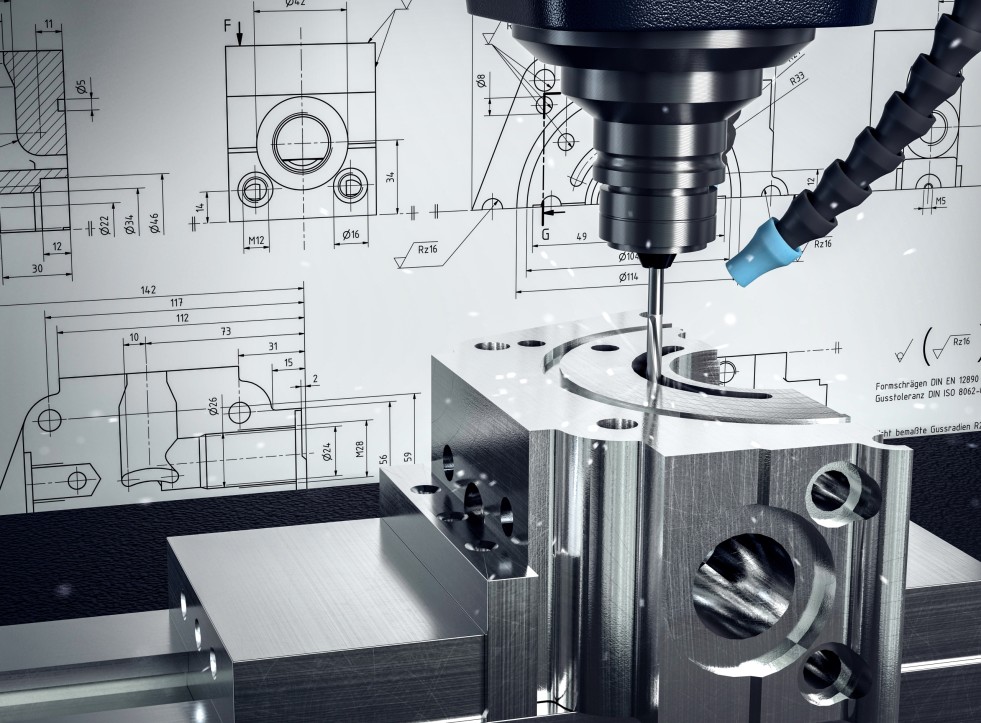

Effective utilization of CNC prototyping is an efficient way for companies to receive small production batch components that provide a functional example of the final product. Unlike computerized models, a physical prototype is a useful tool to identify any design defects to eliminate before proceeding with full-scale production. At K & S Machining, we offer precise and accurate CNC prototyping services with state-of-the-art mills, lathes, routers, and other modern machining equipment. Our fast turnaround times and competitive costs benefit our customers along the Gulf Coast and beyond. This article explores the many benefits and end applications of working with K & S Machining on your CNC prototyping projects, including consistency, material availability, and affordability across industries like aerospace and oil & gas.

The Benefits of Using CNC Machining for Prototyping

While CNC machining can be beneficial for production volumes of virtually any kind, it creates a competitive edge for prototyping. K & S Machining’s CNC prototyping service offers high accuracy and precision thanks to our advanced equipment and technology. At our facility, we have lathes like the Tsugami M08SY II Lathe, which features a Y-axis that allows for off-center CNC milling of complex parts. Our CNC milling machines can also be utilized for prototyping, like the DNM 4000 Mill, which holds 20 tools.

Quick Turnaround Times

While precision is important, a useful prototype must be made quickly, and a CNC system only needs the right computerized code to operate with speed. Our CNC turning machines work with our milling and routing machines to offer quick turnaround times that don’t sacrifice accuracy. This makes CNC machining ideal compared to other methods like injection molding, which can take months to achieve the right mold tolerances.

Consistency

When using CNC machining, prototyping offers a high degree of repeatability, allowing companies to use the same design and process in future productions. Plus, the consistency companies receive offers multiple replicas of the prototype to submit to testing or other modifications. Processes like injection molding suffer mold depreciation from repeated use, but CNC prototyping is consistent throughout multiple uses, creating products that offer dependable quality for later production runs.

Material Availability

Using CNC machining for prototyping means companies can work with a wide range of different materials. This includes plastics, metals, and metal alloys. At K & S Machining, we have experience working with the following materials.

- Low carbon, stainless, and various alloy steels

- Aluminum

- Brass

- Plastics

- Rhodium, and more

Our experience with varied metals, alloys, and plastics offers customers prototyping services using cheaper materials with properties similar to more expensive specialty materials. When using inexpensive materials first, our customers can progress through the prototyping phase at a lower cost before moving on to specialty materials. Additionally, these materials are applicable across multiple industries. For example, the aerospace industry often uses aluminum for its lightweight properties, while stainless steel is popular in marine applications due to its corrosion resistance.

Affordability

Since CNC machining for rapid prototyping is carried out in small batches, the cost of the process is relatively low, especially when you compare it to the cost of discovering a defect after entering full-scale production. K & S Machining offers competitive pricing and turnaround times for our CNC prototyping services, whether you need milling, turning, routing, or any other comprehensive machining services we perform. We function as an extension of our customers’ manufacturing operations, and that seamless integration is designed to be efficient for both production times and your budget.

Industrial Applications of CNC Prototyping

CNC prototyping is an adaptable process that can be applied across a wide range of different industries. At K & S Machining, we have extensive capabilities in the aerospace and defense industries, serving Tier 1 and Tier 2 suppliers. Our team offers rapid prototyping and iteration, adherence to military standards and specifications, and Lean Six Sigma expertise.

Aerospace

The aerospace industry often implements CNC prototyping to ensure their parts achieve high dimensional accuracy. The requirements for components in the aerospace industry to remain compliant with regulatory standards are high, and prototyping using CNC machining has the level of precision required. Of course, the aerospace industry has an additional concern. Parts and components are often subject to harsh environments in the air, so they need the strength to withstand those conditions. The prototyping process allows designs to be tested properly under those conditions (temperature fluctuations, high-pressure environments, corrosive environments, exposure to tremendous force, etc) to ensure they don’t fail after full production.

Defense

The defense industry and its suppliers often use CNC prototyping for research and development. These R&D projects can include components and parts for military vehicles, aircraft, and more. Since CNC machining is faster and compatible with numerous materials like aluminum, carbon steel, and titanium, it is often implemented for new defense advancements.

Oil & Gas

The oil & gas industry uses technology made of components that require pinpoint precision. Oil rig parts and extraction facilities implement complex mechanical engineering that demands parts with extremely tight tolerances. The fidelity of CNC machining can reach those precise standards offering oil & gas companies the ability to carry out prototyping runs for innovations.

CNC Prototyping Services on the Gulf Coast

At K & S Machining, we provide prototyping through our CNC machining services to companies in Alabama, Tennessee, Mississippi, Lousiana, and other regions throughout the Gulf Coast. We have multiple mill-turn lathes, milling centers, programmable routers, and more to create the precision and accuracy defense and aerospace companies need for their prototypes. We serve both Tier 1 and Tier 2 manufacturers and function as an extension of their manufacturing operations for seamless integration.

Our NAICS codes include the following:

- 332710 (Machine Shop) *Primary

- 326199 (All Other Plastic Product Mfg.)

- 332510 (Hardware Mfg.)

- 332999 (Other Misc. Fab Metal Product Mfg.)

- 336412 (Aircraft Engine and Engine Part Mfg.)

- 336992 (Military Armored Vehicle, Tank, Tank Components Mfg.)

The machinists at K & S have the skill and experience to provide accurate results with quick turnaround times. Their expertise and state-of-the-art machines complete prototyping runs promptly with the accuracy needed to test if parts can hold up before entering full production.

Our ITAR-registered machine shop is located in Madison, Alabama, so we can easily deliver to customers throughout the Gulf Coast region, including those in AL, TN, MS, LA, and beyond. Contact our team today to get a quote for your CNC prototyping job!